The pulp egg tray production line is a complete set of paper pulp molding equipment designed to produce plain egg cartons, colorful egg crates, and egg tray boxes with lids for packaging eggs. This small-scale egg tray production line is specifically designed by Shuliy Factory based on years of customer practice, making it suitable for medium and small-sized factories utilizing pulp molding equipment.

The production line consists of various pulp tray machines, including a waste paper pulping machine, an egg tray molding machine, and other supporting equipment. The production capacity of this line ranges from 1,000 to 3,500 pieces per hour.

Moreover, Shuliy Factory can customize a suitable egg tray production solution for customers based on their specific requirements, such as raw materials, production conditions, investment budget, and factory space. With our tailored solutions, customers can efficiently and effectively produce high-quality egg trays while optimizing their production process.

What products can be made with this egg tray production line?

The egg tray production line is versatile and can be used to produce various pulp tray products or pulp molded packaging products, depending on the pulp molding equipment in the production line. This flexibility is achieved by simply changing the molding molds used for egg tray production, enabling the processing of different pulp-molded products.

However, due to the high demand for egg packaging products in the international market, most of our customers choose to utilize this egg tray production line to manufacture egg crates of various sizes and specifications. The most common products produced are plain egg cartons and egg crates with lids, which provide secure and convenient packaging solutions for eggs.

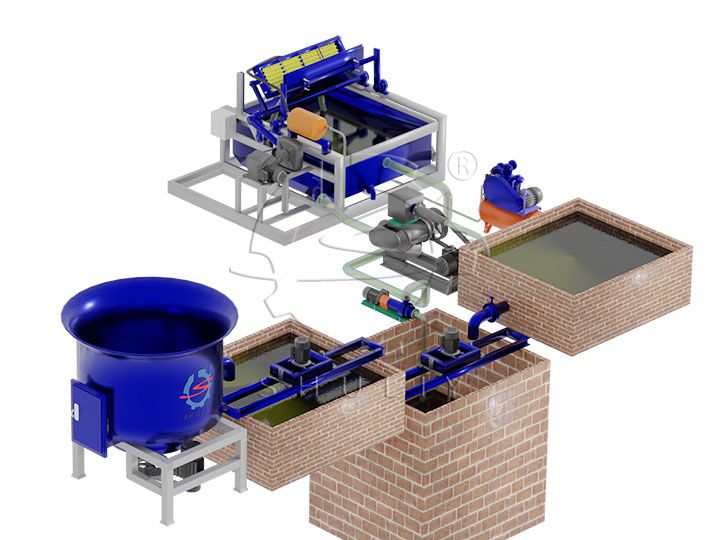

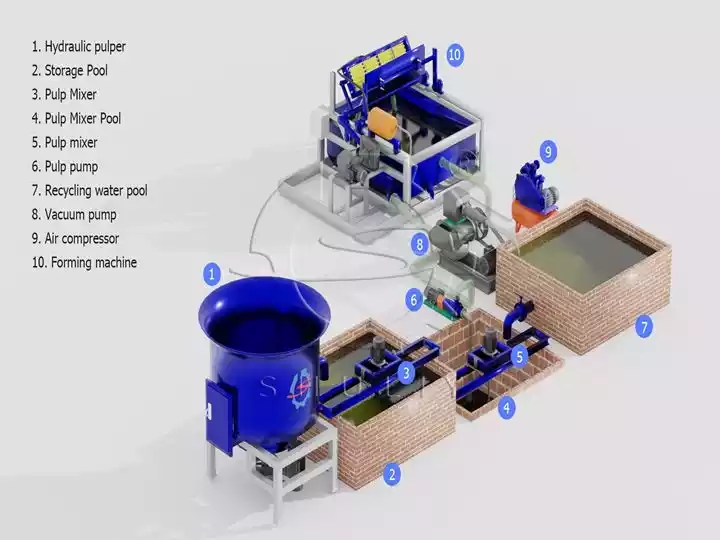

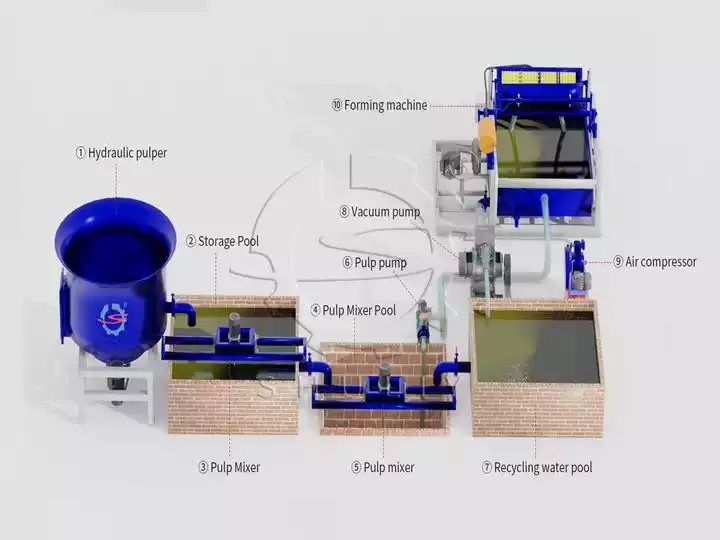

Components of the small egg trays processing plant

The process of utilizing this egg tray molding line to produce egg trays mainly involves pulp preparation, pulp storage, pulp mixing, tray molding, and tray drying. Each stage of this egg tray processing line requires relatively low energy consumption, and the operation methods are simple. Typically, the production process of this line can be handled by only 2-3 workers.

The process starts with the preparation of pulp by breaking down the waste paper, followed by storing and mixing the pulp to achieve the desired consistency. The pulp is then transferred to the tray molding equipment, where it is formed into the desired shape of egg trays. Finally, the molded trays are placed on drying racks or sent to the drying chamber for thorough drying, ensuring their stability and durability. Throughout the entire process, the line operates efficiently with minimal energy consumption and requires only a small workforce to achieve productive results.

Paper pulping

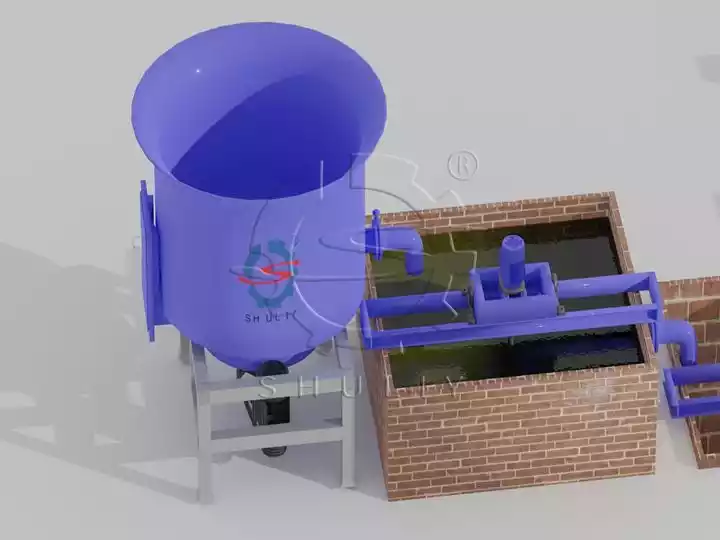

Before using the paper pulper machine, it is common to shred larger waste paper boxes and cardboard to improve the efficiency of pulp processing. The pulper machine is equipped with an internal agitator driven by a motor, which rapidly mixes waste paper and water to create pulp.

The processing capacity of the paper pulping machine varies depending on its model, and the Shuliy factory can recommend the appropriate pulper machine based on the customer’s production requirements. By shredding the waste paper and effectively mixing it with water, the pulp preparation machine ensures a smooth and consistent pulp production process, laying a solid foundation for the subsequent stages of the egg tray manufacturing line.

Paper pulp storing and mixing

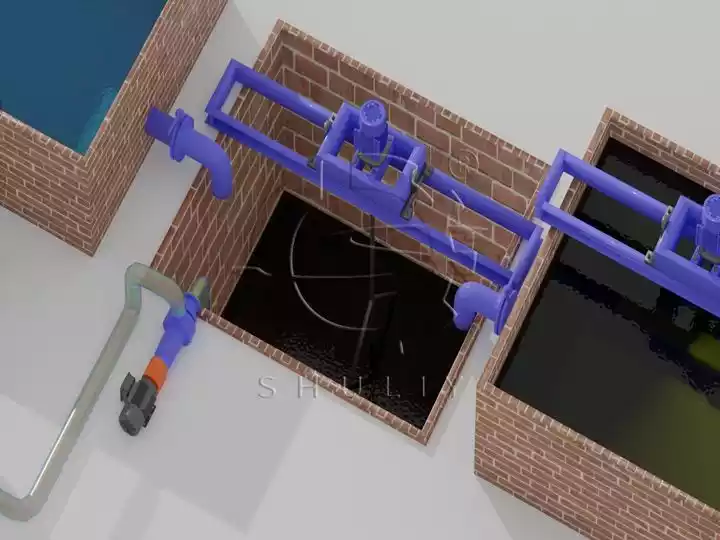

The water pools used for storing pulp are typically constructed by the customers themselves. Shuliy factory, on the other hand, assists customers by providing design sketches for the construction of the tanks based on their factory space. Typically, customers need to build three water pools for the egg tray production process. The first tank is used to store the processed pulp from the pulp preparation machine. The second tank is used for the distribution of pulp from the first tank.

Both of these storage tanks are equipped with agitators to ensure continuous stirring of the pulp and prevent sedimentation and coagulation. The third tank is primarily used to collect water generated by the egg tray molding machine and recycle it for use in the other tanks. This water circulation system optimizes water usage and reduces wastage throughout the pulp tray production process.

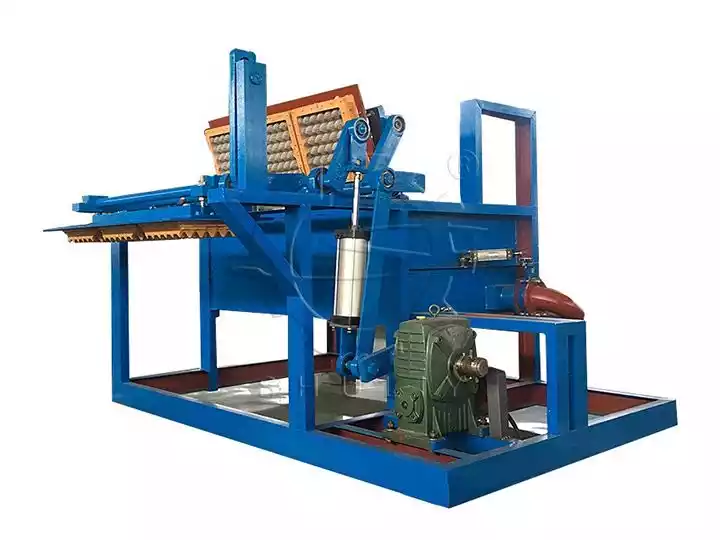

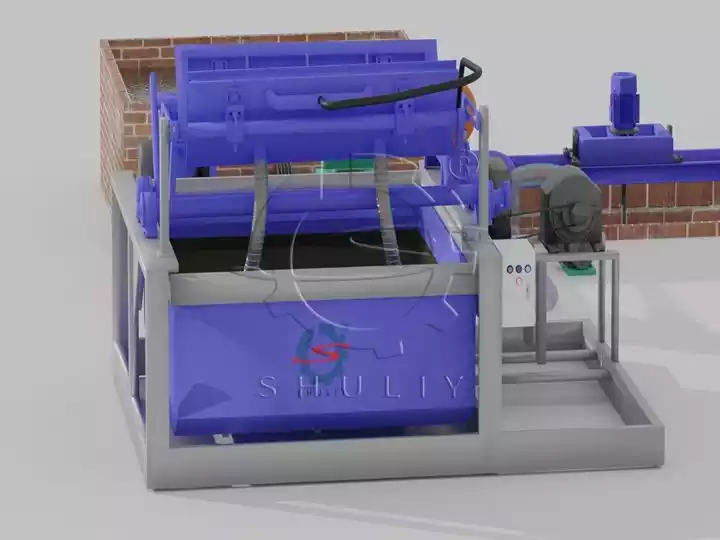

Pulp egg tray molding

The egg tray molding machine is a crucial machine in the entire egg tray production line, responsible for the pressing and molding of the pulp. The pulp is extracted from the pulp pool by the pulp pump and transferred onto the forming molds of the pulp tray molding machine.

Through the close-fitting and squeezing of the paired molds, the water content in the pulp is rapidly squeezed out. The processed pulp trays are then conveyed out of the machine using the transfer molds. This efficient process ensures the proper formation of the egg trays, allowing for subsequent drying and packaging stages.

Egg tray drying

Drying the pulp trays can be done using the low-cost method of natural air drying. Shuliy factory also offers different options for egg tray drying, such as specialized drying machines. When opting for natural air drying, it is beneficial to create wooden or metal racks. These racks enhance the airflow between the egg trays, thereby improving the drying efficiency.

Additionally, our factory provides box-type dryers and continuous multi-layer dryers for rapid and bulk drying of the trays. These drying options ensure that the egg trays are thoroughly dried and ready for packaging and distribution.